0.2M3 / Barrel Feed Port Capacity Asphalt Processing Plant With

Material Lifting System

5Tons Per Hour Asphalt Mixer SLJ-5

Specifications:

1.MODEL | SLJ-5 |

|---|

2.PRODUCTIVITY (T/H) | 3-5 ton/h |

|---|

3.FEED PORT CAPACITY(M3/ barrel) | 0.2M3/barrel |

|---|

4.SUITABLE FOR | ASPHALT,CONCRETE, ASPHALT MACADAM |

|---|

5.COMBUSTOR TECHNOLOGY PARAMETER | |

|---|

(1)FUEL | LIGHT DIESEL FUEL |

|---|

(2)CALORIC VALUE (kal/kg) | 10000 |

|---|

(3)OIL SUPPLY PRESSURE | 1.2MPA(Front nozzle) (variable range 0.6-1.5MPA) |

|---|

(4)OIL SUPPLY TEMPERATURE | |

|---|

a,DIESEL | ROOM TEMPERATURE (FAT-DIESEL OIL HEATED) |

|---|

b,CRUDE OIL (°) | 60 °(Front nozzle) |

|---|

(5)TEMPERATURE: | Room Temperature (variable range From 10 to 300 degree) |

|---|

(6)WIND SUPPLY PRESSURE: | 280mmHg columniation (2.8kpa) Front combustor |

|---|

(7)FLAME SPEED: | 80—90m/s(Max.Spray Speed150m/s) |

|---|

(8)FLAME SHAPE: | Original shpae spread cone angle shape 10° |

|---|

(9)FLAME LENGTH: | 5 times as injection fire diameter (Range from 2 to 12 timees) |

|---|

(10)IMPERFECT COMBUSTION: | less 0.1% charcoal and dust content lesss than 70 mg./M3 |

|---|

(11)FLAME REFERENCE TEMPERATURE: | 2060° |

|---|

(12)BURN OIL/HOUR: | 20kg(variable 15-25) |

|---|

(13)PRODUCE THERMAL/HOUR: | 20 ten thouands kcal.kilocalorie |

|---|

6,SUPPORTING POWER: | rotate ratio(rotate/minute) 19.75kw |

|---|

MAIN ROLLER | 3KW |

|---|

ASPHALT PUMP | 2.2KW |

|---|

Overview:

SLJ-5 Bitumen Concrete Mixer is a new type of mobile bitumen mixer,

which

doesn’t own the specific advantages of simple structure, high

efficacy and turnin

easily, and has its own generator, adopt electronic triggering.

This product used

widely in roads, governments, airdromes and other road

constructions. It is

believed as ideal machinery in modern road constructions.

Descriptions of the Structure and Working Principle

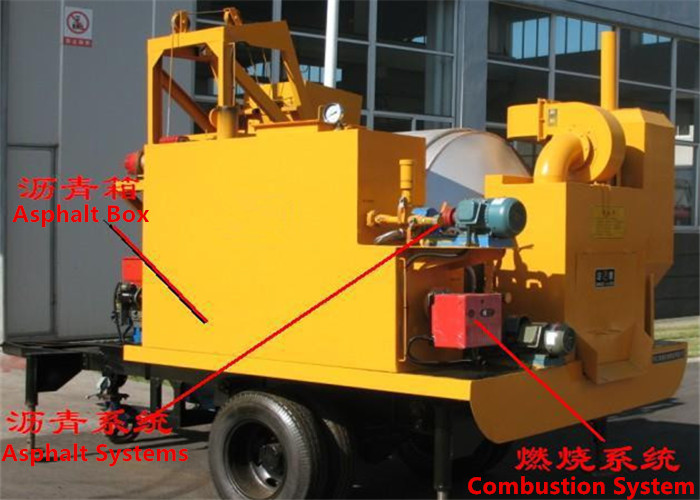

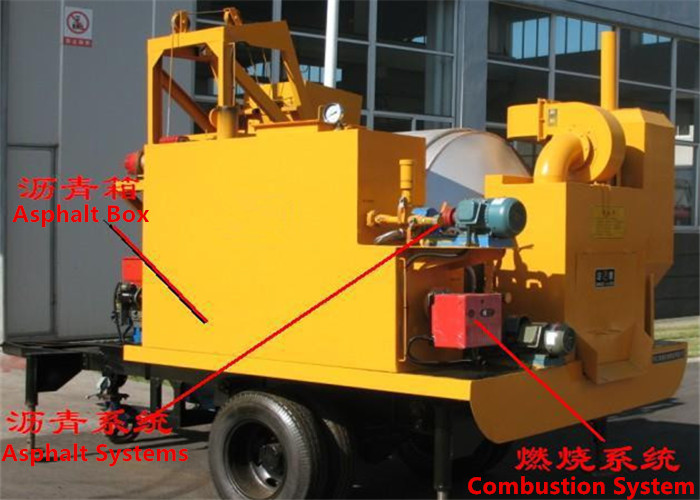

Our product mainly made up of burning system, tumbling cylinder

system, bitumen

system, dust removing system, chassis, and electronic controlling

system, and etc.

Burning system

It is made up of diesel oil pump, blowing fan, electronic igniter

system, diesel oil

box,pipeline and etc. Button igniter use 220V alternating current

through

transformerproduce 10000V high voltage, then produce electric spark

by two

electrode bars,

the diesel oil pump will produce 1.0mpa high pressure oil and via

electromagnetic

valve to control oil pipe switch open or closed.

Ignition and flameout:

1 . Start diesel oil pump to observe whether diesel oil rise or

not, spillover valve

should adjust oil pressure to (1.0-1.5mpa) If the oil pressure is

wrong, must

re-adjust the spillover valve and keep the pressure into the range.

2 . Start the igniting button (two electrode bars produce electric

spark), open the

oil tube switch (electrify the electromagnetic valve, then open the

oil tube, to make the high-pressure diesel oil enter in.)

3 . Observe the fire through the observe hole, to see whether

ignition succeed or

not, if ignition Ok, then start blowing fan, if ignition failed,

stop the electromagnetic

valve and diesel oil engine, after 3 minutes operate it again, this

is very important.

4 . When igniting, must stop the blowing fan, after igniting

succeed, then re-start the

blowing fan.

5 After finish a cycle work, must close the oil tube switch, cut

off the electromagnetic valve power in order to avoid the diesel

oil in when start the diesel oil pump.

6 .When the oil has entered the cylinder could not ignition

immediately, must

remove the redundant oil through the dust blowing fan, further

avoid when ignition

happen "blaster" phenomenon.

Tumbling cylinder:

Tumbling cylinder is combined by cylindrical drum and tapered drum.

Under with

riding wheel and transmission system, material drying, and mixing

are here finished,

the leaves falling lift the hopper raise and down, all of the

mineral formed like a

curtain. Because all the leaves and cylinder welded into a helix

angle make the

mineral move forward and back, there are a couple of spiral leaves

when cylinder

reverse themselves, the mixing materials will be self-unloaded.

Bitumen System:

It consists of bitumen box, bitumen pump, electric motor, pipeline,

and digital display

time relay and etc., when pour hot bitumen into mixer cylinder. The

quantity of

mixing bitumen is controlled by time relay, which set up at a

certain time to control

the bitumen pump to stop at this time, when bitumen pump work to

the set time, the

power will cut off. This process can make sure the fixed quantity.

In order to facilitate the construction of the asphalt road there

are five valves,

respectively called: inner oil absorb port, outer oil absorb port,

inner cylinder spray,

hand spray gun, tank oil input (this valve is on top of the oil

tank)

When mix asphalt, open inner oil absorb port and inner cylinder

spray valve, other

valves closed, so that the oil can be poured into cylinder from oil

box.

When hand spray gun works, open inner oil absorb port and hand

spray gun valve,

other valves closed, then we can use hand spray gun for ground

spraying.

For cleaning asphalt pump, should open outer oil absorb port and

hand spray gun

valve, other valves need to be closed, then the asphalt pump will

be cleaned by

the cycle diesel oil.

Self absorb during refuel oil (in actual use, the best is use other

refueling ways,

since the use of self absorb function; asphalt pump will be easily

bad). Open the

" outer oil absorb port," and the " tank oil input " two valves,

valves remaining

closed, in this way we can absorb the asphalt outside of the tank

into the oil box.

Ventilation and dust removing

There is dust collector cyclone on the back of cylinder, start

draft fan, the dust into

the cylinder will through exhaust flue and fall down, then will be

discharged by draft

fan to prevent pollute environment. At the same time all the dust

pipeline through

asphalt box, using waste heat for asphalt heat preservation.

Material lifting system

Lifting system is composed by cycloid pinwheel reducer, inert solid

elevator bucket

tramroad and the elevator bucket. Then according to mixer ratio to

load the different

granular inert solid into the bucket, the steel wire will drive the

bucket to the stated

height, the longer axis trolley will turn into the turnoff of the

material rest, the bucket

will lean itself, hopper gate will be open so that the material can

turn into tumbling

box through feeding hopper. Then, it will return back to original

position and go

along next cycle.

Chassis

It is a standard trailer chassis, which is made up of turntable,

steel frame, axle, and

spring steel plate, enabling drive while pulling. It is also

installed four stable, flexible

supporting legs to be set up horizontally.

Electric system

Electric system main make up of diesel engine, generator,

electrical components

and etc, diesel oil through Junction box drive the generator, then

the generator will

produce 380v, 50Hz three phase alternating current.